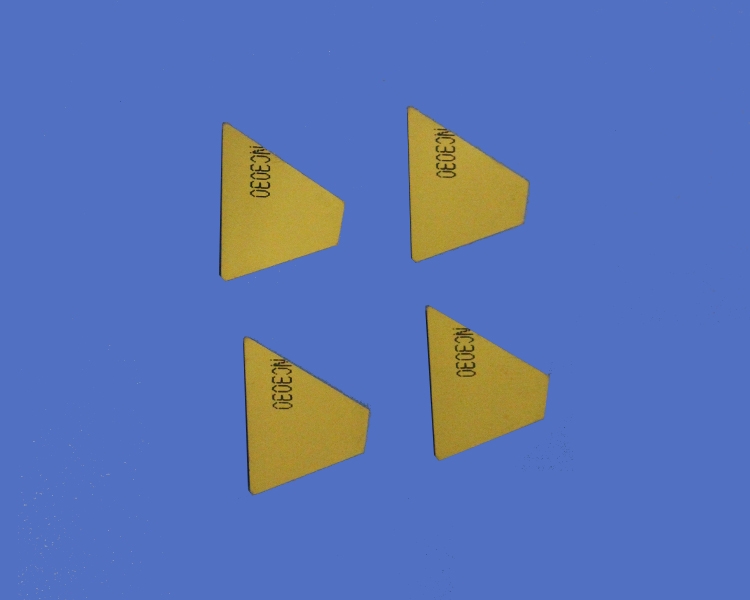

Custom non-standard tool finishing release

Non-standard tool customization is the tool in the mass production of enterprises based on each consumer as a separate market segments, consumers according to their own requirements to design the tool you want, Weddi based on the consumer Design requirements to create the exclusive non-standard tools. Customized non-standard tools to meet most of the needs, to solve the problem of mechanical processing equipment design layout, tailor-made, whether it is size, style, style can be coordinated.

Non-standard tool market continues to improve the demand, is in a how to promote non-standard equipment manufacturers and Dongguan non-standard tool companies to grow together Langkou. Later, the development of ready-made non-standard tools to buy, and now can be based on samples provided by consumers, style display customized non-standard tool expertise, non-standard tool has been advancing with the times. Today's non-standard tool market shuffling heating to speed up the pace, these four major buy points to help you open a whole new concept.

Custom non-standard tool selling point 1-selling process

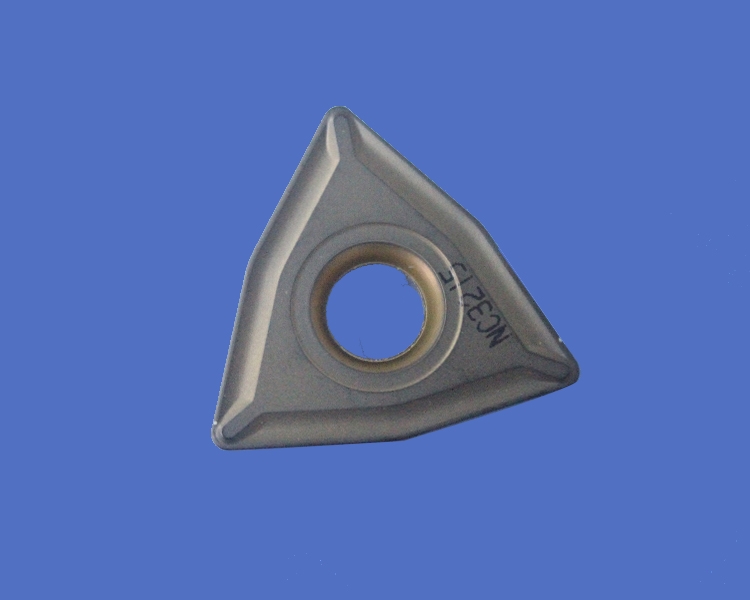

Custom non-standard tools generally refers to the material as the main material custom-based, this technology and style fully in line with modern processing standards, for different needs or custom processing, in short, from inside to outside are required is the perfect process .

Non-standard tool customization process: 1. Selection - select high-quality materials. 2. Casting - Casting is mainly to increase the density of the material, at the same time will produce unnecessary hardness. 3. Annealing - the hardness can be rapidly reduced, in order to facilitate finishing. 4. Finishing - the main billet processing molding. 5. Quenching - will increase the hardness of molded products 6. Insulation - in order to increase the wear resistance of products, we must keep insulation for a long time. 7. Initial grinding - grinding of the surface oxide layer of each product. 8. Grinding mirror grinding --- improve the accuracy of product gloss parallelism and so on. 9. Inspection - Let the non-conforming product refuse to market. 10. Packaging - different packages according to different products. 11. finished product - to be sent. Many processes, time-consuming, anxious, sloppy! This is also the main reason for the slow delivery of non-standard tool production.

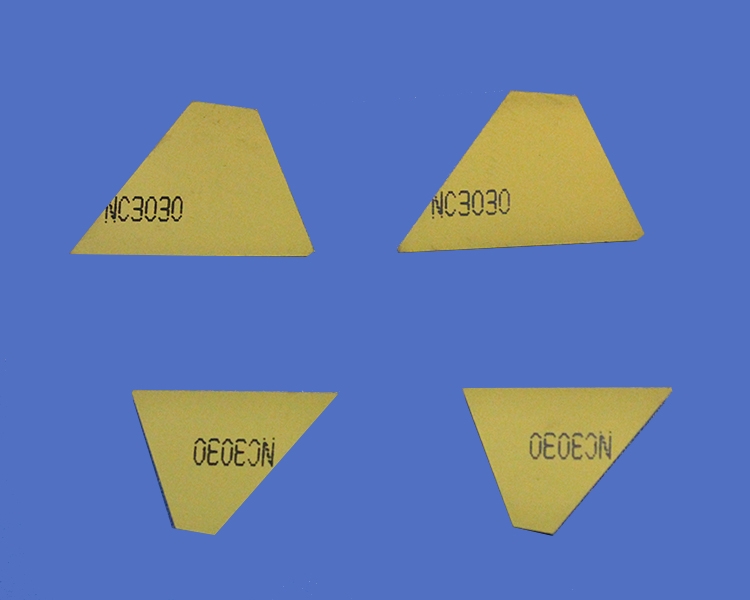

Custom non-standard tool selling point 2-selling beauty

Custom non-standard tool to do well, need one-third of the material, the third division of labor, interlocking details will be the ultimate. Then made of non-standard tools, look at the natural color from afar, smooth lines and beautiful. Close look, realistic texture. This is related to the use of processing technology, of course, so beautiful, nor is it generally a small factory can do. The price is a sub-quality market, the price is only your appreciation of the gap.

Custom non-standard tool selling point 3 - sell service

No matter how non-standard tool manufacturers do well, but still a finished product, you need after-sales service assurance. So bought a non-standard tool, it is the beginning of sales, but also the beginning of service. In accordance with the original negotiation requirements with the drawings perfect installation, acceptance time manufacturers will carefully explain to you the maintenance and use of non-standard tool specifications. From the intention to custom use You always have a caring teacher for your service, it seems that one-stop buttoned!

Custom non-standard tool selling point 4 - selling value

Although non-standard tool development is only a few decades of the scene, custom non-standard tool is nothing but recent events, but we can not ignore the value of today's non-standard tool. Good tool, stand the test, with a few months is no problem. On average, I can not spend a few dollars a day. Non-standard custom tool cumbersome, long-term tracking service, these are higher than the value of the average product. You bought a piece of clothing, wearing a month, broken, others will take care of you? However, custom non-standard tool if there is a problem, the manufacturer will help you to solve, that is, after the sale of manufacturers also only received the cost of parts, buy custom non-standard tool map is this value!

Custom furniture selling point 5 - selling characteristics

Now non-standard tools, all in accordance with your requirements and the choice of harmony and unity, and processing machinery and equipment specifications complement each other, some non-standard tools also according to your wishes processing. So distinctive, you can imagine the original common good intentions, today's happy to meet, I believe the subject of customized non-standard tools must always be dominated by consumer needs.