The Current Situation and Development of CNC Machine Tool Fixture

With the deepening of the industrialization process, the clamps commonly used in CNC machine tools in our country are the combination clamps, the group clamps, the automatic clamps, the numerical control machine tool clamps, etc. Each clamp has its own characteristics. With the modern manufacturing industry to the machining accuracy , The processing speed is higher and higher, making the CNC machine tool fixture is also facing the requirements of replacement, so the design of advanced CNC machine tool fixture so that it can adapt to the needs of modern processing, machinery processing industry has become the focus of attention.

1 CNC machine tool fixture status

With the development of the processing industry in our country, the fixture of the machine tool is also being improved continuously. However, the generality and precision need to be improved, which hinders the development of the CNC machine tool to a certain extent. Many enterprises are constantly improving the versatility of the fixture And optimization, the current machine tool holder has the following:

1.1 combination fixture

In order to improve the use of special fixtures, reduce their scrap rate, these different shapes and sizes of standard special fixture combination into one, so that it can be used in a variety of different machine tools to process different devices, thereby increasing the fixture The versatility, at the same time to ensure that the accuracy of teaching and processing. As the combination of fixtures is a combination of multiple fixtures, so the larger size and weight, in the installation process will cause some inconvenience, and one-time high investment, which limits the promotion of its application.

1.2 group fixture

Group fixture is also a special fixture from the transformation, mainly by the fixed part and replaceable parts of the combination, which can be replaced according to the different parts of the object to be replaced by the corresponding fixture unit to become a new fixture, thereby enhancing the fixture Of the commonality, group fixture is particularly suitable for machining a machine tool of different specifications of the parts of the occasion, after processing a component, you can quickly replace the fixture unit to continue processing another specification parts, it has a high Accuracy, high versatility, and lower than the combined fixture costs, but its degree of automation is not enough to meet the requirements of CNC machining.

1.3 automated fixture

In order to meet the requirements of automated machining, the corresponding fixtures are also speeding up the automation process. In the process of automated pipeline machining, the automatic fixture can be automatically replaced according to the needs of the machining. The entire process does not need human intervention, so the replacement speed is faster. During the process of using the automatic fixture, attention should be paid to designing the process of transporting and replacing the fixture so that the pre-changed fixture can be accurately transported to a predetermined position and quickly replaced by pneumatic, electric or hydraulic power. In addition, due to the automatic high speed Cutting will bring a lot of chips, it must be designed at the same time on the fixture automatic cleaning device, to avoid affecting the cutting work, and to do the fixture and the fixture and the machine contact parts of the lubrication work to prevent wear in the process is too large, and Because of the continuous persistence of pipelined processes, these efforts require pre-programmed procedures that can be done unattended.

1.4 CNC machine fixtures

With the rapid development of mechanical processing industry, CNC machine tools have been widely used, CNC machining tools with higher machining accuracy, processing speed, conversion of processed products easy to achieve, a high degree of automation, suitable for use in a variety of different specifications, types Workpiece processing and high-precision, multi-process, small batch of workpiece processing, CNC machine tools, put forward higher requirements on the fixture: First, the fixture to have high-precision machining requirements, and be able to do their own rapid replacement Second, the fixture should have a good openness and mobility, the coordinates of the machine coordinate system is clear, the data is simple, easy to coordinate conversion calculation; Finally, some CNC machine tools require the corresponding fixture also needs With the tool to help support the function of automatic knife.

2 CNC machine tool fixture development

2.1 Standardization

In order to reduce the cost of jig itself, CNC machine tool jig should develop in the direction of standardization under the premise of achieving universality, that is to say, the standard of jig for all kinds of jig should be made based on the current national jig and jig, Make the machine tool fixture become a kind of standardized machine tool ancillary equipment, help to promote the commercialization and large-scale production of the machine tool fixture itself, and reduce the cost of the fixture itself.

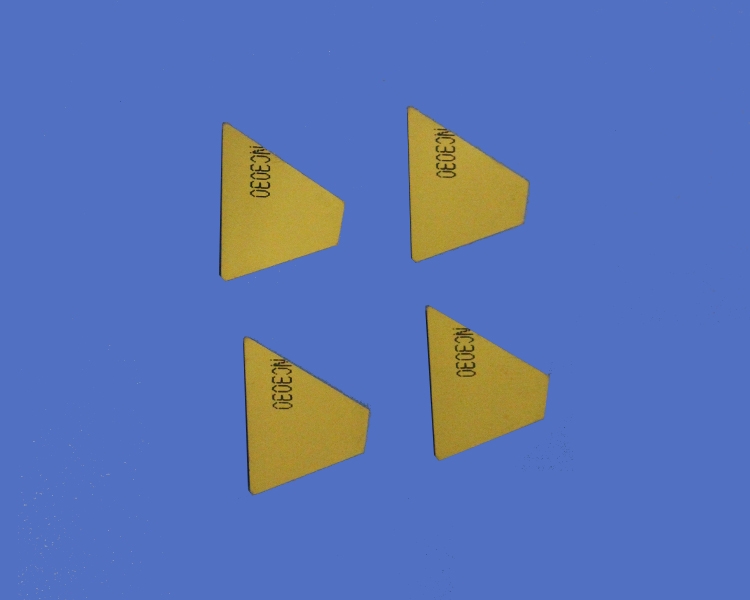

2.2 precision

With the increasing demand for the precision of machining products in various industries, CNC machine tool fixtures are required to develop toward high precision. The precision of the fixture is mainly reflected in the design of the fixture structure. The current more precise fixture structure There are three claws self-centering chuck, multi-gear plate, etc., in the structural design of the fixture to give full play to subjective initiative, in order to achieve greater precision machining direction.

2.3 efficient

With the increasingly fierce competition in the modern machining industry, machining enterprises are required to maximize their work efficiency. Therefore, CNC machine tool clamps also put forward higher requirements. First, as a machine tool fixture, it can meet the requirements of high-speed machining and minimize Fixture auxiliary time to improve the productivity of machine tools to maintain the continuity of work and safety in production, using machinery to replace manpower, greatly reducing the labor load of workers. For example, in the high-speed lathe using three-jaw self-centering chuck clamping the workpiece, you can adapt to nearly 10,000 rpm high speed machining conditions, and if the use of electric vise to clamp the workpiece, compared with manual clamping efficiency 5 Times above, greatly improving the machining efficiency, is conducive to achieving the company's profit target.

2.4 Flexible

Fixture flexibility is through the scientific design of the fixture structure, the non-removable mechanism into a removable mechanism, so that it can be adjusted by their own combination to meet the needs of various processes, a variety of combination of fixtures, a group of fixtures are However, with the demands of high precision and high speed of modern machining, the simple and flexible design has become inadequate. Therefore, it is necessary to design a structure that is more reasonable and has higher precision, and can be automatically disassembled and replaced by a detachable fixture Part of the work will greatly improve the efficiency of the fixture, so as to provide better support for modern processing.

Conclusion

In summary, with the modern manufacturing industry on the workpiece manufacturing requirements are getting higher and higher, CNC machine tool fixture is moving in the direction of standardization, precision, high efficiency, flexible direction, and it is foreseeable that with the development of science and technology More advanced machine tool fixtures will emerge. Therefore, as fixture designers, it is necessary to give full play to creative thinking and continuously design machine tool fixtures that conform to modern processing concepts to promote the steady development of the processing industry.